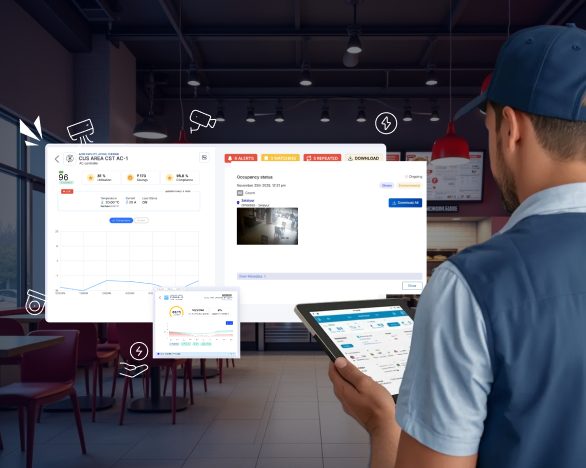

As a manufacturer, your primary aim is to achieve seamless production, meeting demands without interruptions while maintaining uncompromising quality. However, delays and downtime in production can lead to significant costs and inefficiencies.

At Atsuya, we understand the importance of maximising productivity while minimising costs and environmental impact. Our solutions are carefully engineered to address specific challenges on the factory floor such as downtime, quality control issues, and operational inefficiencies that can significantly impact your bottom line.

Challenges

Unplanned equipment downtime disrupting production

Unmonitored over-run hours

Inefficient energy usage

Costly repairs due to inaccurate maintenance forecasting

Compromised quality due to poor equipment condition

Lack of digital records for poka-yoke, quality patrolling and other audits

Environmental sustainability