The Challenge

This leading garment manufacturer sought to leverage the power of data to implement energy management systems and improve operational efficiency. They were also looking to streamline their manufacturing processes by integrating cutting-edge technology across their facility and significantly enhance sustainability in their operations.

Our Solution

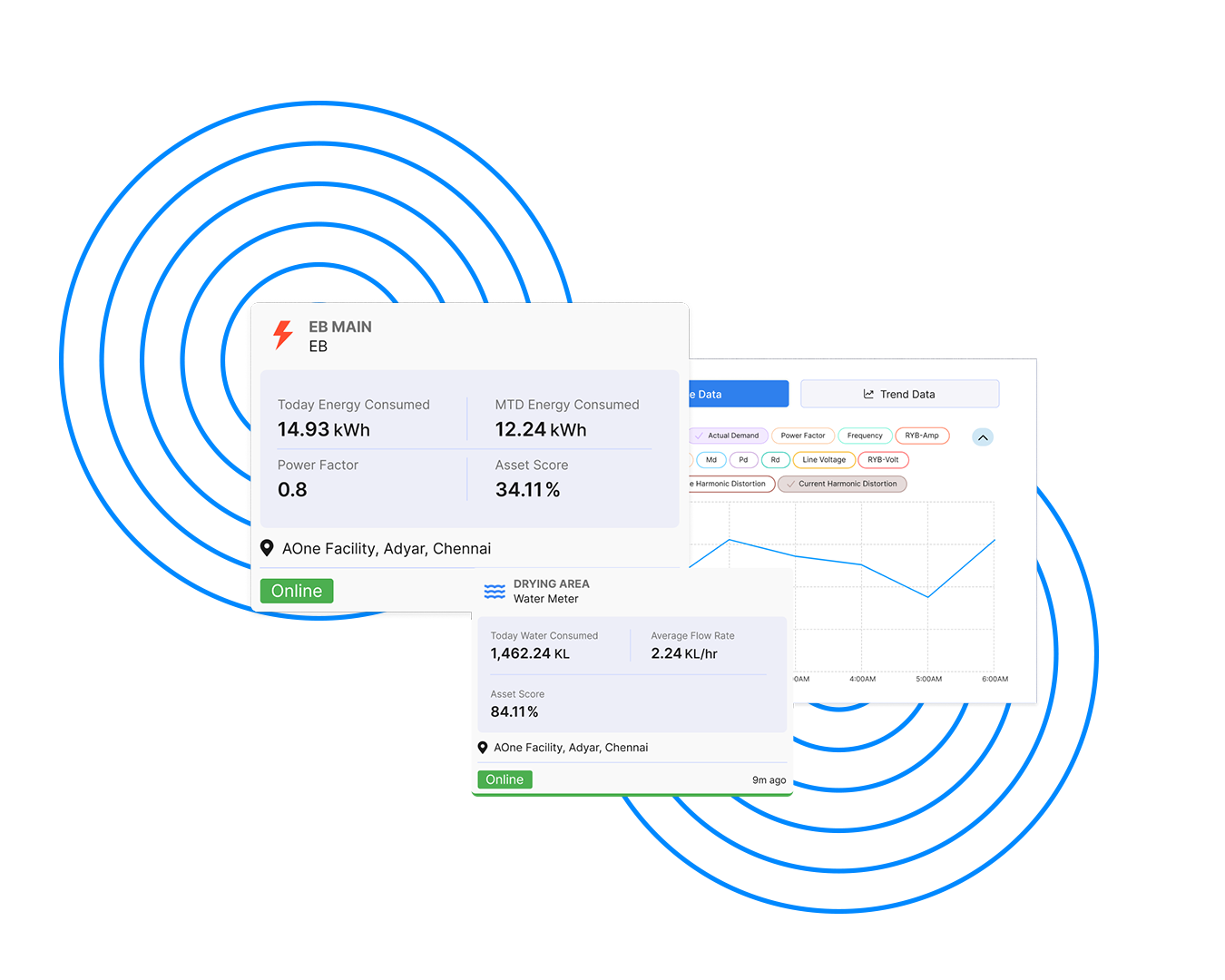

We deployed the AOne IoT sensors across the client’s facility. This helped them track their energy consumption and monitor all equipment in real-time. Additionally, AOne also facilitated predictive maintenance, which resulted in lesser asset downtime and improved production efficiency. With AOne, the client achieved transparency in resource consumption, optimised their processes, and incorporated sustainability into their operations.

We also integrated the AOne AI-based unified dashboard that centralised data accessibility and offered comprehensive insights which facilitated informed decision-making.

– Equipment-wise energy utilisation monitoring

– AI-based data insights for optimisation

– IoT-powered monitoring of overall energy balance

– Real-time data on product-wise-specific energy consumption

– Prompt alerts in case of compressor demand fluctuations

– Equipment health monitoring and predictive analytics

– IoT-based water consumption monitoring

– Production efficiency and productivity tracking