A wealth of information creates a poverty of attention, said Herbet A Simon (1916-2001) a renowned American economist, political scientist, and computer scientist.

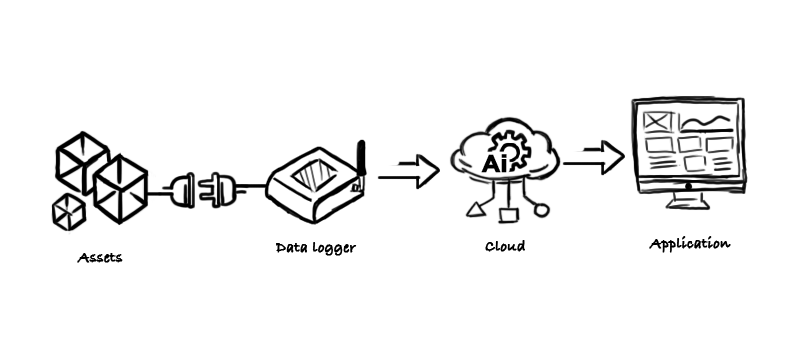

In a business, every asset generates data. This wealth of information, comprising productivity, consumption, maintenance, serviceability, etc., plays an integral role in our daily operations. Thanks to advancements in Generative AI and Large Learning Models (LLM), our interaction with this data has been revolutionised. Conversational chatbots and learning engines enable us to engage with our data, extracting invaluable insights with ease.

But how do we leverage this intelligence within our assets and the data they produce? One approach is to embed intelligence directly into the assets themselves. This can be achieved by integrating sensors and data loggers at strategic points, or by utilising data ports enabled by the Original Equipment Manufacturer (OEM).

Intelligent assets, empowered by IoT, AI, and real-time data analysis, are poised to redefine asset management. By continuously monitoring and analysing data, they optimise performance, significantly minimise downtime, and facilitate the integration of sustainability practices into businesses’ operations. Their adaptive nature and capacity for learning not only drive efficiency but also foster innovation and enhance overall business competence.

Example 1

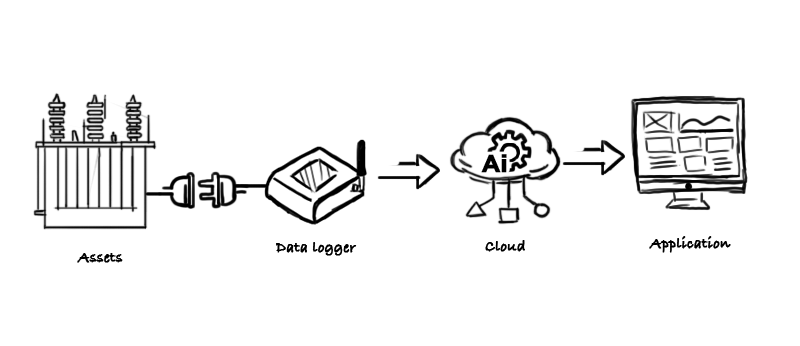

Example 2

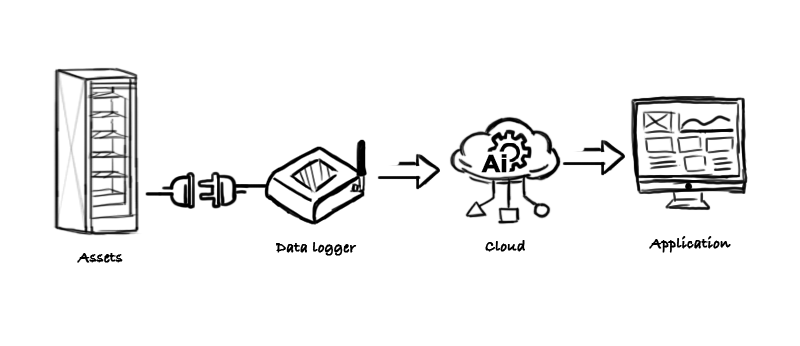

Example 3

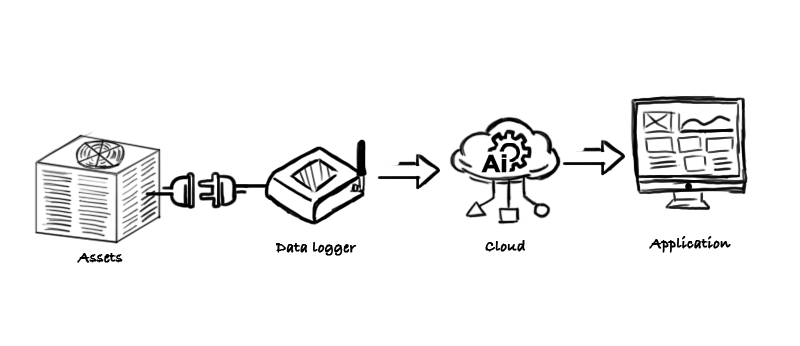

The next section will discuss a few ways businesses can leverage data to maximise savings. Read on!

Leveraging Data to Maximise Savings

In today’s highly competitive business environment, businesses must integrate intelligence into their operations. This can not only help businesses stay ahead of their competitors, but also enhance efficiency, productivity, and profitability.

Data-first businesses save big, as they will be leveraging technologies like AI, IoT, and ML, which will improve decision-making and drive innovation. Data can help businesses achieve operational efficiency, resource and supply chain optimisation, predictive maintenance, and more – these are indicators of savings.

If you aspire to be a data-first organisation, here are two important steps that will help you get started:

I. Defining a Digital Roadmap

Businesses with the help of internal champions and experts must begin by defining the desired outcomes, followed by identifying critical points to be monitored and controlled to achieve the desired outcomes. An assessment of the existing infrastructure is an important first step. This assessment should include:

1. All assets (machines and meters), their make, model, and year.

2. Assets classified into critical, good to have, and luxury.

3. Protocol and communication ability of digitally enabled assets (if any).

4. Mode of communication – wireless or wired.

5. Wireless connectivity available inside the premises (Wifi, GSM (2G – 5G) signal strengths) at the location of the meters.

– Does the existing wireless infrastructure have the necessary bandwidth to consume the data sent by the new smart devices?

– What are the IT policies which need to be adhered to when establishing/utilising the wireless infrastructure?

6. Security requirements for communication and handling of data

Once the assets to be digitised are identified, the next steps include:

1. Business requirements/rules around desired operating parameters, for example:

– Temperature to be maintained in a cold room based on the inventory classification.

– Compressed air utilisation per day.

– Instantaneous air pressure to be maintained.

2. Escalation matrix listing the names and contact of people responsible, SLA (Service Level Agreements) for each type of breach in rule with the hierarchy of escalation in the event of non-compliance / non-action within the prescribed period.

3. Decision to build in-house based on available capability vs using a readymade off-the-shelf product vs identifying a partner to build the solution.

II. Treading the Digital Path

Once a solution and roadmap are finalised, execution involves identifying the timelines, working closely with the partner (internal or external), and ensuring a smooth transition to the new system. Though an off-the-shelf IOT solution is expected to be live from minute one, it is only achievable if the pre-preparation is good. Additionally, the system should be operated/compared with any manual or existing data collection mechanisms to validate the consistency/reliability of data and communication.

Any business should plan up to 3 months to stabilise any large implementation involving over 100+ sensing nodes. Change management becomes a critical exercise for the success of any digitisation initiative. Business needs to factor in the usability of incoming solutions as well as sufficient training to be provided to the on-ground users. Assigning an internal champion to manage expectations and ensuring timely rollout of necessary changes is critical for success.

Success Stories

Let’s closely look at three use cases where intelligent assets have helped achieve efficiency across industries.

Case 1. Frozen to Perfection

Leading grocery retail chain in India embraced digital solutions for improving its quality and compliance.

The digital solutions implemented include:

– Store wide utilities monitoring.

– Procurement and planning management

– Staff performance tracking & audit

The benefits accrued are:

– Predictive asset maintenance

– Eliminating redundant inspection

– Easy sustainability reporting

Key milestones achieved are:

– 18% reduction in energy consumption across various stores

– 12% reduction in operational costs

– 15% reduction in asset downtime

Case 2. Keeping it cool Through Energy Efficiency

A popular mall in Malaysia implemented IoT over its traditional Building Management System to improve efficiency of its operations.

The digital solutions implemented include:

– Integration to BMS over Bacnet

– IOT enabled temperature monitoring of common areas

– AI enabled analytics of ahu & chiller plant data

The benefits accrued are:

– Reduce energy bill

– Reduce overrun hours

– Improve asset performance

Key milestones achieved are:

– 15% savings on monthly energy bills

– 20% improvement on HVAC equipment utilisation

– 20% reduction in equipment breakdown

– 25% improvement in occupant comfort

Case 3. Patching the Air Leaks

A leading automobile component manufacturer in India implements digital solutions to patch leaks in operations.

The digital solutions implemented include:

– Energy management

– Water consumption management

– Equipment health monitoring

– Predictive maintenance

The benefits accrued are:

– Reduce energy bill

– Record specific resource utilisation per product manufactured

– Improve asset performance

Key milestones achieved are:

– 18000m3/annum savings in compressed air consumption

– 50% fewer cases of energy voltage shoot-ups and load balancing downtime

– 50% reduction in line pressure stabilization time

– 27% reduction in compressor downtime

– Improved specific energy and specific water intensity accounting

Conclusion

At Atsuya, we have worked with organisations across a wide range of industries and helped them digitise their operations. With experience, we believe, businesses can expect to see results in 12 to 36 months. The return would be both direct and indirect. Smoother operations, better forecasting and reduction, penalties and surcharges, improved productivity and removal of redundant operations are immediate benefits. With data and targeted intelligence comes visibility and opportunity to operate efficiently, thereby bringing in substantial savings directly and indirectly to organisations.

If you are looking to digitally transform your business operations, get in touch with us at marcom@atsuyatech.com.