The Challenge

In axle manufacturing, precision defines performance and quality compliance is inseparable from safety. Even a minor surface defect or dimensional deviation can compromise load-bearing capacity, resulting in rework, warranty claims, production delays, and, most critically, a risk to on-road safety and customer trust.

Traditional manual inspection, often dependent on visual checks and handheld gauges, is not only time-intensive but also prone to human error. Scaling such methods across multiple variants and lines makes quality consistency difficult to maintain.

One of India’s leading axle manufacturers sought a digital solution to:

- Achieve 100% reliable defect detection

- Ensure compliance-ready traceability for every part

- Optimise inspection time without impacting throughput

The Solution

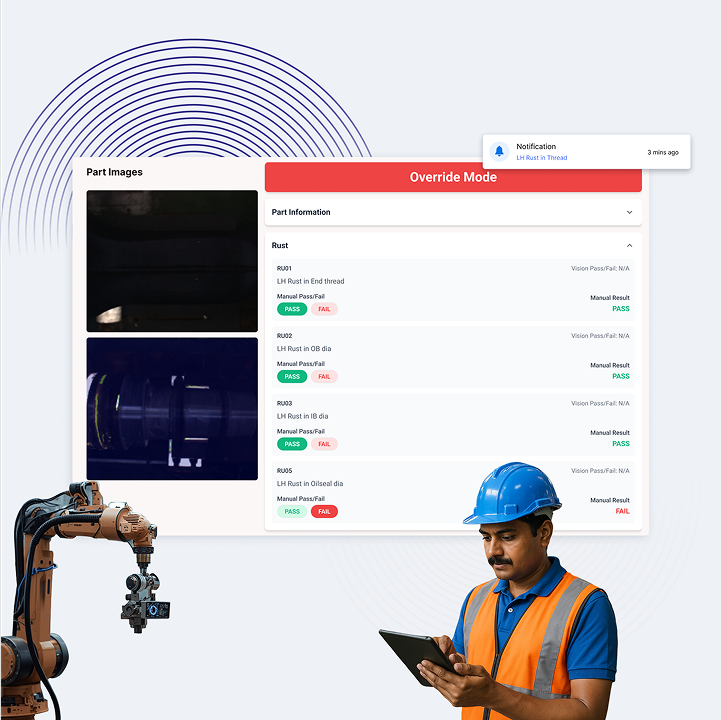

AOne deployed a computer vision–based automated inspection system, powered by AI and robotic automation, seamlessly integrated into the existing production line and quality workflow.

How it works:

◉ QR code–based identification links each axle housing to its unique part and serial number, enabling complete traceability through every process stage.

◉ A robotic arm, with programmable scanning routines per axle variant, captures high-resolution images under calibrated lighting conditions.

◉ A custom-trained vision model library, developed specifically for axle inspection, detects multiple categories of surface and assembly defects such as:

– Rust and corrosion

– Paint drops, overspray, and coverage gaps

– Tool marks, dents, and machining scratches

– Welding cracks, porosity, and joint faults

– Missing studs, breather holes, and flange-hole irregularities

◉ All inspection results are logged in real time on the AOne dashboard, creating a digital record for every axle, accessible instantly for analysis and audits.

Technical Highlights

- Adaptive AI models: Self-learning algorithms fine-tuned using historical defect data for each axle model.

- Non-intrusive integration: System retrofitted to existing conveyor and handling setup without production downtime.

- Intuitive dashboard: Combines visual analytics and operator logs into one traceable record.

- Edge + Cloud architecture: Enables local inference for low latency and cloud storage for long-term data retention

Adaptive optics and lighting: Custom illumination profiles for each axle variant to ensure uniform image capture and minimise false positives.